When you work in a demanding industry like construction, your safety should always remain a top priority. One way to achieve this is by focusing on protective gear that will enhance how you meet the demands of your field. Safety glasses, for example, play a crucial part in keeping you safe and sound. Of course, you don’t want to pick any goggles. Part of securing yourself at work involves selecting gear like z87 safety glasses that have been tested in accordance with strict standards and can guarantee your protection.

ANSI Standards

There are a few key points to focus on when selecting the most appropriate prescription safety glasses for your needs. For one, an ANSI rating can be an indication of a quality product. The American National Standards Institute is a third-party organization responsible for testing and ensuring the quality of various products. When you discover a pair of safety glasses that have been given an ANSI rating or designation, it means that you can trust in the protective power of this eyewear and what it can provide for your overall safety.

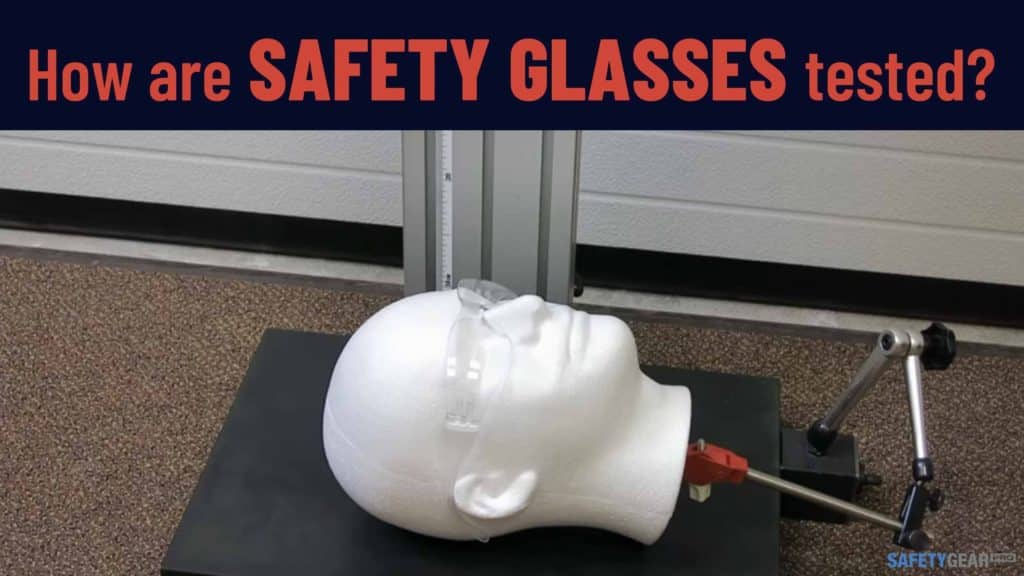

Basic Safety Tests

Glasses meant for safety are tested in a number of ways. One classic approach used by organizations like ANSI is the “drop ball” test. To conduct this type of quality assurance test, a researcher will drop a ball made of a heavy material like steel on the lens from a specific height. In order for the eyewear receive an approval from ANSI, the steel ball cannot cause any damage to the physical appearance or general integrity of the lens. This is one of many tests used to guarantee the effectiveness of safety products and gear.

Advanced Safety Tests

Since these lenses must be able to withstand more than a simple steel ball drop, testing for high impact situations is also conducted. Typically, this test will involve shooting a steel ball at the lens at a distance of about 150 feet. To receive an ANSI rating, the lenses must not show any signs of damage or become dislodged from the frames. When you work with complex machinery or pressurized environments, protection from a sudden and fast impact can make all the difference for your health.

Tests for Prescription and Non-Prescription Lenses

There are key differences in how prescription and non-prescription lenses are crafted. In order to compensate for this, tests conducted to assure safety standards are slightly different depending on the prescription status. Non-prescription lenses are both thinner and weaker by design. Safety tests surrounding these lenses will not usually be as intense as those for thicker prescription options. While thinner prescription lenses were once an issue for safety tests, standards have changed to allow lenses with a minimum thickness of 3 mm.

FAQs

How Do I Know My Glasses Have a Safety Rating?

If you currently wear glasses and want to know if the eyewear your own meets safety standards, the answer can be easily found. Manufacturers mark eyewear that meets safety standards with a “+” symbol. If your eyewear has this symbol in the manufacturer’s markings, it means it has an appropriate rating for safety.

Are Regular Glasses Also Safety Glasses?

On average, a standard pair of glasses used for reading, driving, or basic daily activities are not going to be considered safety glasses. If you’re required to wear specific glasses for safety at work, while playing sports, or for any other purpose, it is crucial that you invest in a pair that meets the requirements and keeps you protected.

What Does z87 Mean on Glasses?

When you see eyewear with a designation of z87, it means the glasses have met the standards of the American National Standards Institute. If you have any doubts about whether or not the safety goggles you require are satisfactory for your line of work, the z87 mark should offer the peace of mind you need.

What Does OSHA Say About Safety Glasses?

The Occupational Safety and Health Administration dictates the rules and regulations surrounding workplace safety. For glasses, OSHA states that protective eyewear is required in any position where an employee is exposed to eye or face hazards like flying particles, chemicals, dangerous gases or vapors, and more.

Do Safety Glasses Have an Expiration Date?

Just because you own glasses for safety does not mean the eyewear is still up for the challenge. According to experts, your glasses should be changed roughly three years after you purchased the pair. This helps to guarantee the performance of the glasses over the course of time. Every industry comes with a fair share of risks and dangerous demands. Whether you work in construction, a research facility, a manufacturing plant, or a high school science lab, protecting your eyes is an absolute must. Learn what you need to know about OSHA standards for your field and explore the vast selection available at Safety Gear Pro. Once you know more about what you’re looking for, it will be much easier for you to discover an appropriate pair of glasses that will shield you from the most common threats associated with your workplace.