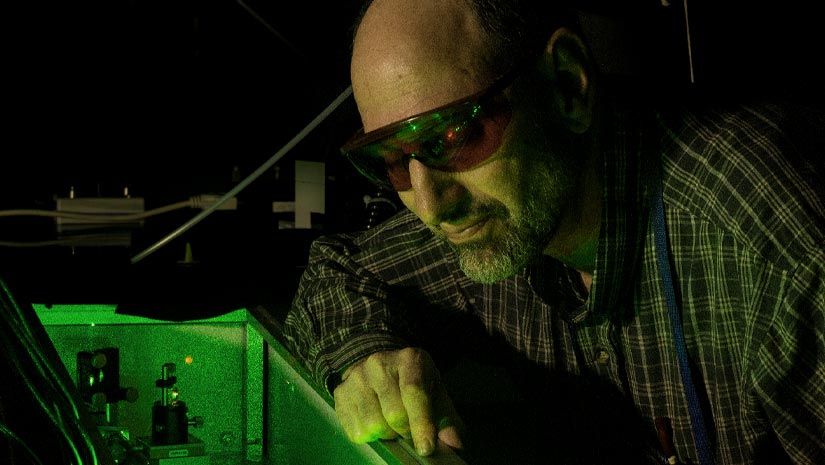

When you work with high-powered laser lights, you need to protect your eyes. Laser safety glasses are used in a wide variety of fields, including in the military, in research, and in the medical field. They are available in a wide variety of styles, with the style you need depending on whether you’re working with Class 3R, Class 3B, or Class 4 lasers. Despite their different levels of protection, all laser safety goggles work in a similar fashion.

About Filtration

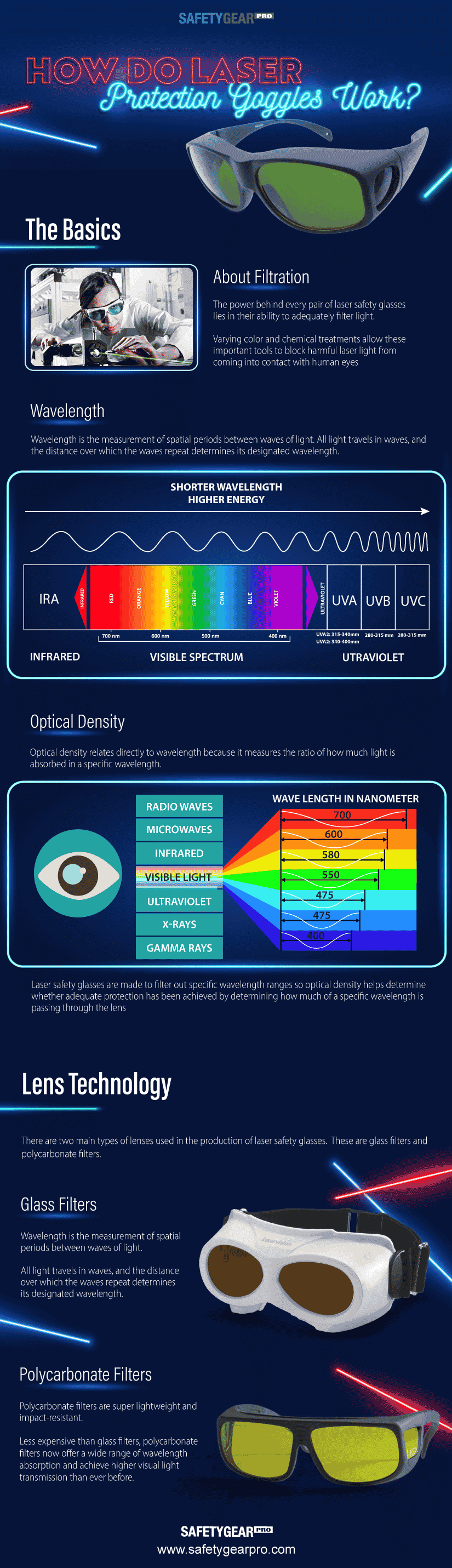

The ability to filter light adequately is the most important feature of any pair of safety goggles. They are designed to interrupt harmful wavelengths of light before they reach your eyes while still allowing the light you need to work to penetrate them.

Wavelength

To ensure that you have the right pair of safety lenses for your job, you need to know the wavelength of the lasers that you’ll be working with. Wavelength is defined as the measurement of spatial periods between waves of light. All light travels in waves that repeat at regular intervals. The distance between the waves is what determines the wavelength of a laser. All light has these distinctive high and low patterns, which are known as crests and valleys. They are measured in something known as nanometers. Every light has a wavelength that ranges between 700nm and 400nm. A 700-nm light is what we see as dark red, while a 400-nm light is what we see as violet. Safety lenses have the primary concern of filtering out problematic light from the electromagnetic spectrum.

Optical Density

Understanding optical density is also important. Optical density is the term that describes how much light a lens can absorb, which thereby determines at what strength it can block out waves of light. Optical density is directly related to wavelength since it measures the ratio of light absorbed to a specific wavelength. Laser safety glasses are made to filter out only specific ranges of wavelengths. Therefore, knowing the optical density helps to determine whether you are providing enough protection for your eyes while you are working with laser lights.

Lens Technology

Now that you understand the importance of wavelength and optical density, it’s important to know that lens technology is a determining factor that helps you decide which goggles are right for the type of job that you’re doing. There are two main types of lenses used in laser-protective prescription safety glasses: glass filters and polycarbonate filters.

Glass Filters

Glass filters are the least technologically advanced option of the two, but that doesn’t mean that they aren’t important. In fact, several wavelengths require glass protection to ensure that your eyes are as safe as they can be while you work. Glass filters allow more visible light to be transmitted to your eyes, which means they are the best option if you are working around mid- to high-density laser powers. Some companies provide custom combined glass filters, in which increasing the thickness of the lens increases the optical density levels.

Polycarbonate Filters

The more technologically advanced of the two lens technology options are polycarbonate filters. These filters are lightweight and impact-resistant, which make them more comfortable and often safer to wear on the job, especially if you are also at risk of dust or debris entering the eye. Despite being the newer of the two technologies, polycarbonate lenses are often less expensive than glass filters. They offer a wide range of wavelength absorption and also are able to achieve higher visual light transmission than they used to. Polycarbonate-filtered lenses are best if you are working around low- to mid-power lasers. Like glass filters, they can be customized to meet your specific needs in most cases.

FAQs

1. Are Protective Goggles Really Necessary?

Yes, protective goggles are necessary when working with any type of laser light. Unlike skin, the retina of your eye does not contain any pain receptors. This means that you won’t be able to tell if a laser is doing any damage to your eye. Without protective glasses, serious damage can occur before you even realize there is a problem.

2. How Long Does Laser Protective Eyewear Last?

Simply put, it depends on how well you treat your safety equipment. While absorptive filter protection does not lessen over time, coated eyewear will typically only provide protection as long as the coating doesn’t become scratched. If you notice any defects, such as damaged metal enforcements or changes in the color of the filter, you should avoid using the glasses and purchase a new pair.

3. How Do You Clean Laser Safety Eyewear?

Cleaning your laser-protective glasses is much like cleaning your eyeglasses. Use clear water or a neutral cleaning agent to cleanse them, then dry them gently with a soft cloth. Avoid cleaning them dry, which can damage any coatings, and never immerse them in water. Avoid chemicals, sterilization solutions, and ultrasonic waves.

4. Can Laser Protective Eyewear Be Repaired?

In many cases, yes, your protective eyewear can be repaired. Contact the company from which you purchase your eyewear to learn about its repair policies.

5. Are There Universal Pairs of Laser Protective Eyewear?

There is no scientific way to create a universal pair of laser protective glasses. The only materials that can cover all types of lasers are steel or other materials that do not transmit any ultraviolet or infrared radiation.

Get Your Prescription Safety Glasses Today

Now that you know how laser protective eyewear works and why you need it, it’s time to choose your pair. Get your laser safety glasses at Safety Gear Pro.