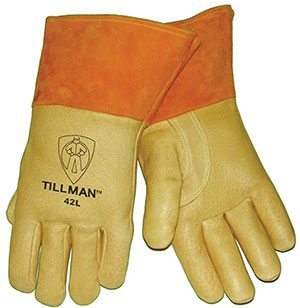

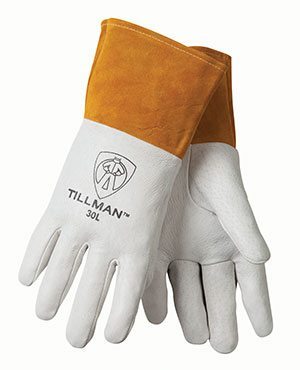

Gloves may be intended for TIG, MIG or stick welding. Dexterity is the primary factory for precision TIG processes. MIG welding generates more heat with a risk of sparks and splatters. Stick welding requires the highest level of hand protection.

Welding Gloves

Welding Gloves Videos

WATCH REVIEWS ON WELDING GLOVES

Showing all 17 results