The Fundamentals of How Safety Glasses Are Made and Tested

Investing in the right safety glasses is not a decision to be taken lightly. Whether you wear these goggles for work, when playing sports, or while at the shooting range, you want to be certain the ones you pick are up for the job. Understanding what makes for a quality pair of glasses comes down to understanding a few critical details about how safety eyewear is made. If you’re looking to purchase new glasses, now is a great time to look over the finer details and get a better feel for the basics.

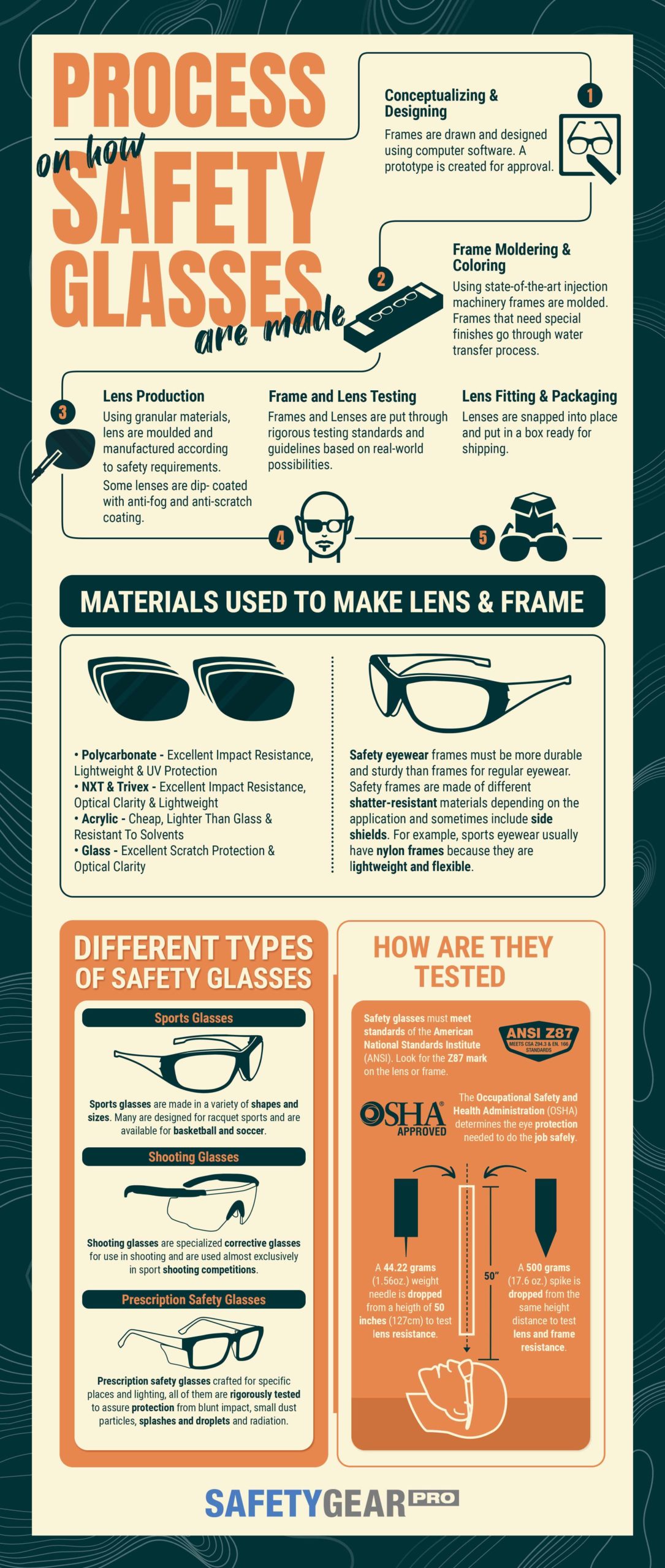

How Safety Glasses Are Made

The first thing to understand about how prescription safety glasses are made is that the gear needs to adhere to specific standards in order to qualify as actual safety products. The regulations are dictated by both the Occupational Safety and Health Administration and the American National Standards Institute. These organizations create quality assurance standards based around testing against some of the biggest physical risks people face across a variety of industries and activities.

Glasses that are approved by these organizations are made from materials that are tested time and time again in a variety of ways. Both the lens and the frames must meet standards individually and as a finished piece of gear.

The Importance of the Lens

While safety goggles are measured based on a few key standards, the lenses are the most vital when it comes to the standards set by ANSI and OSHA. There are four general options when it comes to lens material. Polycarbonate lenses are the most commonplace, as the material is resistant to scratches, lightweight, and durable. Still, the other options have unique advantages. Trivex lenses are said to feature improved clarity. Similarly, plutonite is a very unique lens option that is made specifically for the Oakley brand.

Glass lenses are easily shattered and the least protective in high-risk environments, but can be a useful material to consider for labs or environments where impact is not a concern. Since glass is incredibly resistant to scratches, it can be a fitting option when the circumstances allow. The frames are also important for safety glasses, but in most cases the frames are designed around the dimensions and demands of the lens. To guarantee the standards are met, the eyewear will be tested as separate components and as a finished product.

The Process of Testing Safety Glasses

Understanding the unique methods used when testing safety goggles can help provide better context for how to select a pair that meets the demands of your lifestyle. There are several ways this is done. First, glasses are put through rigorous tests to see how the materials fare against sudden and intense impacts. Both the lenses and frames must be deemed shatterproof in order to meet the highest of safety standards. Additionally, the materials must be exposed to various chemicals and sources of non-ionizing radiation to guarantee the glasses will block fumes.

Finally, to receive the proper designations, z87 safety glasses are put through trials by actual fire. Flames and corrosive substances are used in tests to ensure the goggles will not melt or catch fire. Once the eyewear meets all of these standards, it receives approval from the American National Standards Institute and can be trusted to provide superior protection in a variety of circumstances.

Selecting the Best Pair for Your Needs

The more you know about the strict standards used when testing safety glasses, the easier it is to invest in a pair that will help you stay protected no matter what. Take time to look through all of the options available to you at Safety Gear Pro and see which relate best to the risks you face. When you understand what the ratings mean and how different lens materials function, you can select gear that helps you get more from your personal safety goals.

FAQs

What are the best safety glasses?

The best safety eyewear fits comfortably and is rated to protect eyes from potential hazards. Glasses that meet the American National Standards Institute Z87.1 standard provide at least basic impact resistance. Some Z87 safety glasses are rated for high mass and high velocity impact protection and other exposure risks.

How does safety eyewear work?

Safety eyewear provides physical protection by covering the eye area. Durable frames and shatterproof lenses can be helpful for absorbing impact, limiting irritant exposure or shielding eyes from damaging light. Safety eyewear may reduce the severity of injuries to the eye socket area as well as directly to the eyes.

What is the strongest frame material?

The most durable frames are made of titanium and titanium alloys. Nylon and Triloid frames are more flexible than most metal frames, but glasses frames made of synthetic polymers break more readily than metal. Over time, sun exposure makes nylon brittle. Some titanium alloys, such as Flexon, are very flexible.

What type of lenses are in safety eyewear?

Safety eyewear generally comes with shatter-resistant polycarbonate lenses. This lens material is thin and lightweight, even with stronger prescriptions. Polycarbonate can scratch easily. Select a scratch-resistant lens coating and store glasses in a cushioned case when not in use. Other safety lenses may be made of NXT, Trivex or Plutonite.

How do I get prescription protective glasses?

Select a pair of safety glasses rated to protect your eyes from hazards at work or during any activities. Enter your prescription measurements to make sure frames are compatible with the strength of lenses. You may have the option of single vision or multifocal lenses that are clear or tinted.

Related Articles

- 5 of the Best Prescription Safety Glasses on the Market

- Tips for Protecting Your Eyes While at Work

- Best Rated ANSI Prescription Safety Glasses

- Do Safety Glasses Block Ultraviolet Light?